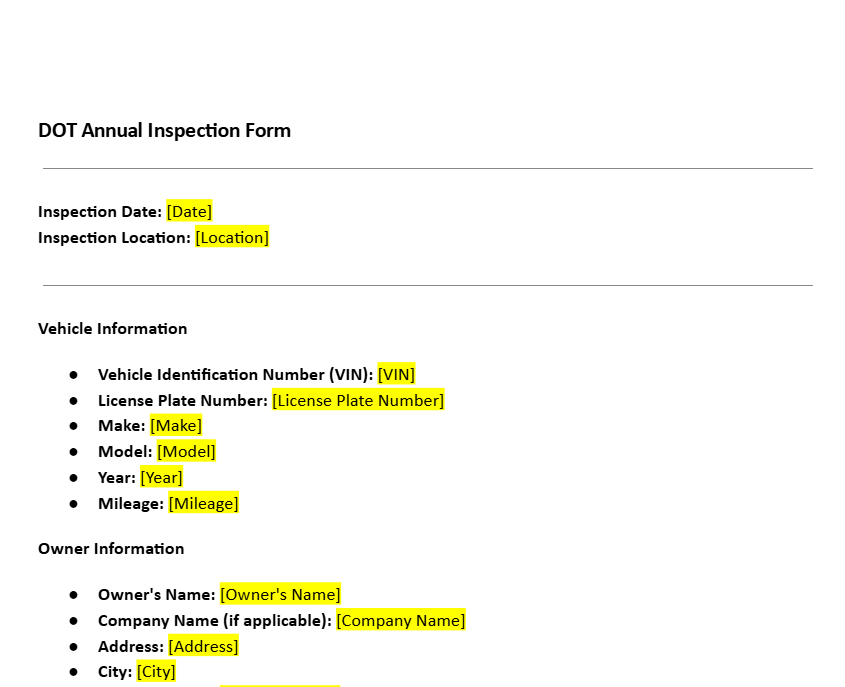

DOT Annual Inspection Form Template

8 Downloads

Commercial

March 4, 2025

Sayantani Dutta

Regulatory compliance in the trucking industry necessitates frequent checks on commercial motor vehicles in a quest to uphold road safety. A key part of this process is the DOT annual inspection, a government-mandated vehicle condition report. The procedure is documented on an inspection report, which is the permanent record of the enforcement of federal motor carrier safety regulations.

Any carrier who operates a CMV must maintain a record of such ratings. An inspection is required annually by the Department of Transportation to ensure critical vehicle systems meet a minimal standard of safety. If this documentation is not completed, fleets face fines, penalties, and operational disruptions.

This process applies to trailers and other commercial motor vehicle categories under CFR 396. A completed DOT vehicle inspection report is a record of vehicle inspections conducted on a periodic basis, which serves to reduce liability risk for operators and fleet managers.

The Provisions in a DOT Annual Inspection Form

An inspection report form provides a detailed report on various vehicle parts in line with FMCSA requirements. The purpose of this document is to ensure all functions of the vehicle perform in a satisfactory capacity, minimizing mechanical breakdown risk.

Each component of the form captures critical data on mechanical systems, structural stability, and safety devices. Without thorough documentation, vehicles may fail compliance checks, leading to unnecessary downtime and regulatory issues.

Vehicle Identification

A valid DOT record of inspection begins with vehicle identifying information. This includes the make, model, year, and VIN of the vehicle, which facilitates easier identification of inspected assets for fleet managers and regulatory authorities.

Inspectors can document power units, license numbers, and fleet-assigned numbers so that completed vehicle yearly inspection reports align appropriately with equipment in operation.

If vehicle identification is not followed, it can make it difficult for records to be verified, particularly in fleets of commercial motor vehicles. Accuracy in this section makes it easier for record-keeping so it can be quickly accessible for compliance audits.

Braking System

The braking system is one of the most critical areas of a DOT vehicle inspection. Failure in this system can lead to severe road safety threats. Brake discs, the parking brake, and brake drums are examined for proper operation.

The test includes examining for excessive wear or damage, along with correct hydraulic brake, electric brake, and air compressor operation. Low system air pressure in braking systems or a malfunction in a vacuum system may pose a threat to vehicle safety, necessitating urgent repair. A well-functioning braking system ensures stopping power, reducing accidents on urban streets and intercity roadways.

Steering and Suspension

The steering system and steering mechanism must work with minimal play, misalignment, and wear. Technicians check steering linkages, gearboxes, and column connections to confirm functionality. Suspension parts play an equally vital role, keeping the vehicle in position under load, and maintaining a smooth ride.

Inspectors evaluate subframe connections, U-bolts, and other elements that impact handling and stability. A well-maintained suspension system not only provides improved driver control, but it ensures even tire wear, and voids excessive wear and tear on vehicle components.

Lighting and Electrical Systems

Adequate lighting is a necessary safety requirement for commercial motor vehicle operation. For a DOT inspection, the lighting systems, headlamps, brake lights, turn signals, and markers must be in proper operating condition. Technicians test the electrical system and if dimming or flickering is apparent, additional electrical issues may have to be addressed before releasing the vehicle report.

Fuel System and Exhaust Systems

Leaks in the fuel system or exhaust system pose major environmental and safety threats. The fuel connections, fuel lines, and fuel tanks are examined for signs of visible leaks and corrosion, which can lead to spillage.

The exhaust system is examined for faulty routing so fumes exit safely and don’t enter the driver’s cabin. Faulty exhaust systems can result in excessive noise pollution, along with failed emissions inspections, making this test an integral part of the DOT yearly inspection process.

Couplings and Load Securing Devices

Vehicles used for towing must have thorough checks on coupling devices, pintle hooks, and drawbars to avoid trailer detachment. Inspectors check for excessive wear, cracking, or loose fasteners on connection points, which can pose a risk in transit. Along with towing units, inspecting officials look at secure loading systems. Cargo securing systems must comply with federal regulations to prevent shifting cargo, which can lead to road instability or accidents.

Windshields Visibility

Inspectors examine windshield wipers, mirrors, and glass for integrity, making sure there aren’t major cracks or blockages. Drivers must have an unobstructed view of traffic and the road. If a windshield crack is in a driver’s line of sight, repair or replacement may be required before it returns to operation.

Tires and Rims

Inspectors check the tread depth, wear patterns, and inflation levels to confirm roadworthiness. Faulty tire pressure and bent rims can lead to bad handling and an increase in fuel consumption.

Any evidence of excessive tire wear, bulged sidewalls, or visible steel belts must be addressed immediately. The lug nuts are tightened by technicians so the wheels won’t loosen during vehicle operation on the road.

Stickers and Decals for Regulatory Requirements

When a vehicle is inspected, a sticker or decal is placed on it as a visible record of compliance. This credential provides regulatory officials with an assurance that the vehicle is FMCSA safety-compliant. Vehicle defects must be repaired before being issued a DOT yearly inspection sticker. Failure to make the necessary repairs can result in restricted operation until all repair work is completed.

Finalizing the DOT Inspection Report

When all of the fields on the annual vehicle inspection report are completed, the inspector makes a final determination on compliance. If cleared, it’s signed and documented as part of the firm’s record of compliance. If there are identified failure points, these must be repaired before releasing the vehicle for operation.

A documented record of inspections provides a valid record of compliance, which is a valuable point of reference for audits, road checks, and internal fleet inspections. From steering mechanism operation to road lights, every constituent contributes its role to optimal road safety.

Why a DOT Annual Inspection Form Is Necessary

Driving commercial motor vehicles on an invalid DOT record is a major risk. Being in compliance with CFR 396 and FMCSA regulations is a legal issue, not an optional bureaucratic process. Safety inspections create a platform for vehicle safety, regulatory conformity, and operation efficiency.

Omitting a DOT vehicle inspection or conducting it improperly can lead to fines, legal trouble, and the vehicle being taken off the road. Apart from compliance, keeping DOT forms current improves fleet operation and lowers operating and maintenance costs in the long term.

Regulatory Compliance

The federal motor carrier regulations set stringent requirements for vehicle safety. Each carrier must have its fleet inspected once a year by the DOT and have its results documented on an official yearly vehicle inspection report. Failure to keep these records can result in serious fines and citations for fleet operators.

If an inspector makes a request for documentation and a motor carrier is unable to provide a completed annual vehicle inspection report, the vehicle can be removed from operation. The cost of non-compliance can extend beyond fines, affecting business capacity and reputation.

Liability Protection

Accidents resulting from poorly maintained commercial motor vehicles result in complex legal cases. When a collision occurs, the investigators will look at the vehicle’s maintenance record. A well-documented vehicle inspection is a verifiable document that proves that the vehicle was inspected and is in full compliance with all safety regulations.

Legal defense is complicated when there is a dearth of documented evidence of compliance with federal motor carrier safety regulations. Accurate documentation is a mechanism for minimizing liability risk since it provides evidence of the necessary safety checks and maintenance.

Fleet Longevity and Maintenances

A well-regulated DOT annual inspection process plays a valuable role in fleet longevity by preventing mechanical issues before they lead to expensive breakdowns. Daily inspections of brakes, hydraulics, the fuel system, and the exhaust system provide a gauge of each vehicle’s roadworthiness.

Early repair of minor issues avoids breakdowns, keeping repair costs and vehicle downtime to a minimum. Fleet managers who employ a proactive program involving DOT forms of inspection can reduce breakdown repair risk, enhance vehicle reliability, and smooth out operational efficiency.

Along with mechanical durability, DOT vehicle reports provide historical data used in making predictions for major repairs or replacements. Monitoring the steering mechanism and tire wear patterns permits advanced scheduling for repairs, creating maximum cost savings over the long term.

Insurance and Risk Management

Many fleet operators fail to consider the role of DOT yearly inspection reports in determining insurance costs. Insurers consider vehicle maintenance histories when establishing coverage levels and pricing. A fleet with a proven record of satisfactory DOT vehicle inspections and filing yearly vehicle inspection reports can be eligible for lower premiums.

A record of failed inspections is bad news for insurers. Vehicles cited for mechanical breakdowns or safety non-compliance present greater risk, translating to higher insurance premiums. A well-managed fleet based on thorough DOT inspections reflects proactive risk management, lowering risk, which is attractive to insurers.

Operational Efficiency

Following FMCSA regulations not only prevents legal issues and fines, it also makes fleets more efficient. Entering DOT forms into an organized system facilitates streamlined administrative functions.

Instead of scrambling for documents during on-site audit inspections, or on-road checks, fleet managers can access them instantly for compliance and inspection purposes.

Technicians can refer back to past vehicle inspection checklists when comparing the results of current inspections, ensuring scheduled maintenance is in alignment with safety requirements.

Minimizing Unscheduled Maintenance

Unplanned mechanical breakdowns disrupt logistics, increase delivery times, and create serious operation-related issues. Vehicles taken offline as a result of failed DOT inspections create a strain on fleet operations. Regular filing of the annual vehicle inspection form makes it possible to detect potential breakdowns before they lead to major service disruptions.

Unplanned downtime translates directly to lost income and elevated operational costs, especially when a breakdown necessitates urgent repair. A detailed report of inspections on each vehicle allows managers to identify potential issues and address them in advance.

Compliance During Roadside Checkpoints

Roadside inspections are made by DOT enforcement officials in accordance with federal motor carrier safety regulations. Vehicles may be inspected randomly, and operators should have valid DOT forms in possession when requested. Having valid decals or stickers of recent inspections discourages lengthy detention of the vehicle for compliance in enforcement stops.

Carriers who persistently fail to file valid annual vehicle inspections face increased audits and more frequent inspections. A system of keeping DOT forms readily available to drivers and inspection authorities avoids unwarranted delays.

Enhancing Driver Confidence and Protecting Public Safety

Vehicles kept in a well-maintained condition lower the chances of accidents due to mechanical malfunctions. Safe roadways depend on functioning braking systems, secure coupling mechanisms, and well-maintained lighting systems.

An annual DOT inspection is a legal procedure verifying all safety requirements are up to standard. Compliance-focused fleet operators enhance highway safety and protect the carrier, drivers, and the public.

Using a DOT Inspection Form Template for Compliance

Manual processing of DOT forms is not an effective or efficient process. A template facilitates the process with a formatted outline capturing all aspects of the inspection in line with CFR 396 and FMCSA regulations.

Standardized documentation reduces errors and improves record-keeping accuracy. A number of fleet operators use templates, which comply with industry regulations and integrate with fleet management systems for live tracking of periodic inspections.

The use of a printable or digital template streamlines admin work. Standardized DOT forms of inspection minimize paperwork inefficiencies and ensure every commercial motor vehicle in the fleet is in regulatory compliance.

Download a DOT Inspection Form Template with a Free Trial of FreshDox

Safeguard your commercial fleet and download a DOT inspection form template from FreshDox with a free 7-day trial of our platform. Sign up for a Basic or Premium account at no charge and get immediate access to our entire archive of professionally designed templates for business. Our templates are completely customizable, edit them and download your form in PDF or Word format. Sign up today and explore the value FreshDox offers your business.

Popular searches:

Related Templates

Discover more templates that align with your needs and preferences.

Ready to Sign Up?

Sign up for FreshDox.com’s 7-day trial and discover why so many individuals and businesses trust us for their legal document template needs.

- Cancel any time

- 7-day free trial

- From 300+ Customer Reviews